Tile Warehouse was requested to supply 8000m2 of Greek 'Volakas' Marble to the floors of the 277 Westfield Mall in Newmarket, Auckland currently being refurbished.

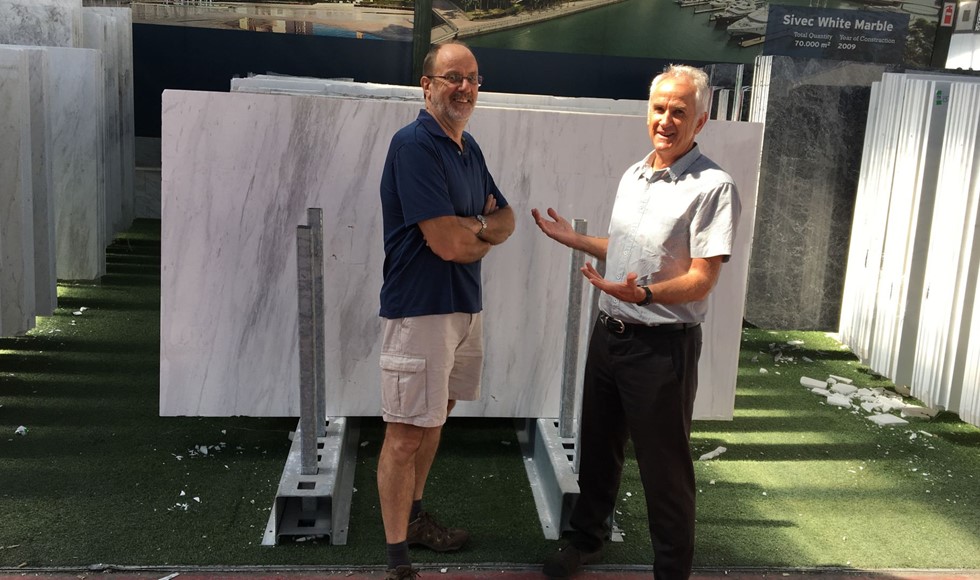

This project is being managed by the Managing Director, Neville Colbert & Commercial Manager, Stephan Englebrecht.

How did the project come to pass by Tile Warehouse?

We have been working with Westfield/Scentre Group (SG) for over 7 years with different flooring/Marble options for the revamp of 277 so there had been a lot of interaction. Prior to this, we had supplied tile to a number of Westfield's across NZ.

Why did Scentre Group choose to partner with Tile Warehouse on this particular Westfield project?

SG was looking for an organisation that had the scale and financial strength to deliver operationally as well as substantial knowledge and expertise. They chose Tile Warehouse because we have in-depth knowledge of natural stone, the logistics to manage a project of this scale, and an understanding of SG's requirements. Also, the Volokas Marble we submitted met their design requirements.

As part of the tendering process, we had to submit samples which is where our combined stone experience helped. We could see the issues and discussed in depth with SG how to manage these.

Why 'Greek' Volokas marble?

The SG design team selected Volokas as the right look even though using natural marble in shopping malls in NZ is not common. However, SG is very experienced in shopping mall sealing, cleaning and maintenance so understand the requirement's from both an installation and maintenance perspective.

How many months of planning was involved before product selection?

Planning to product choice took at least 8 months from the time we started to submit samples with different options. Post selection was a visit to Greece with the SG to agree on control samples. Then the hard work started!

What were the Challenges?

There were multiple challenges in that the specifications and QC requirements were very precise, with tight timelines. Matching the control sample holds a challenge in that when you are dealing with a natural marble that’s quarried from blocks then cut, all the natural variations are realised and from one marble block to the next. It can also be difficult to match a designer's requirement and vision of end look with the reality of what comes from nature. To combat this with the least disruption, we put QC checking processes in place and Stephan, our Commercial Manager visited Greece to ensure correct material selection of a huge shipment working alongside a local Greek QC.

Regarding supply, after a lengthy tendering process we carried out due diligence and checked all incoming material - 40 containers worth, by hand! 300 pallets were sorted removing tile that was outside the control samples and re-imported additional stock at no charge to SG.

Stephan, as well as one of our Commercial team, are still on-site weekly, working with the two tiling gangs, ensuring all the material is up to our high standards. It is fair to say our stringent control requirements and attention to detail was not always well received but our client has expectations and our role was to deliver on these, so it was a prerequisite to a successful project.

The scale of the operation that is required to look after the logistics on a project of this size and the timelines is no mean feat. With close to 40 containers for the project arriving in New Zealand, this was a significant undertaking by Tile Warehouse. We are also assisting with the provision of Basalt for external areas as well as food courts.

What has become very clear though is that SG group appreciates all the effort our commercial team put into the source and supply of the Volakas marble and has looked to us on multiple occasions to solve other stone and tile requirements since.